http://www.gmls4.net/index.php*Update: Feb 2020 cable drive for TB

https://www.amazon.com/92mm-Black-Throttle-Body-Cable/dp/B07T726LPC/ref=asc_df_B07T726LPC/?tag=hyprod-20&linkCode=df0&hvadid=362794770459&hvpos=1o2&hvnetw=g&hvrand=5786699140190809570&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9025450&hvtargid=pla-816888630176&psc=1&tag=&ref=&adgrpid=74430839645&hvpone=&hvptwo=&hvadid=362794770459&hvpos=1o2&hvnetw=g&hvrand=5786699140190809570&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9025450&hvtargid=pla-816888630176*Update: What all is involved in removing DOD? I don t want to have to deal with it !!

*To Disable DOD? Just unplug the wires to the solenoids - the connector directly under the Intake's neck.

*You may not be able to keep to original ECM. It depends on the year LS4 and on the ECM you have. 2005, and I think the 2006's used the E40 ECM, newer ones use the E67 ECM's. Those engines also used a different reluctor wheel, so you can't use a different ECM without swapping reluctor wheels.

Here is information on the engine and transmission in the LS4 front wheel drive cars. I have slightly condensed it to be more readable. The complete GM documention copied into Word Document format is attached. I re-read it several times, but if something doesn't sound right or make sense send me a PM. Any updates or suggestions are welcome.

the LS4 is 23 3/16" from the bell housing to the forward edge of the harmonic balance /pulley. The length of the block is 20 3/4" and the leading edge of the #1 bank is flush with the face of the block. The top of the intake is 17 1/2" above the crankshaft center line.

Generation IV 5.3L LS4 V8 Overview

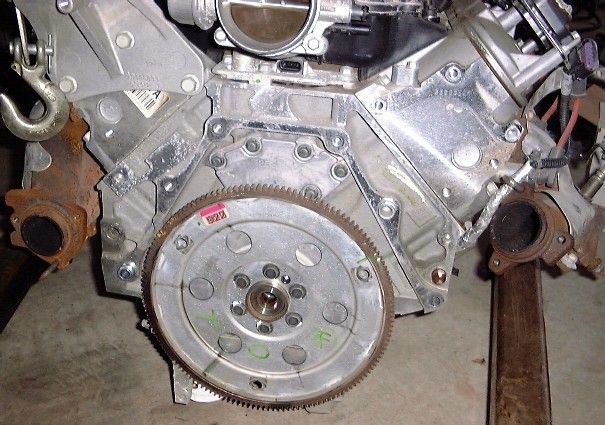

The 5.3L LS4 shares the basic architecture of the 6.0L LS2. This includes an all aluminum block, six-bolt main bearing caps, deep-skirt cylinders, and a structural oil pan. It has the 243 casting LS6 heads with LS1 valve springs, which are good for 6200-6300 rpms.

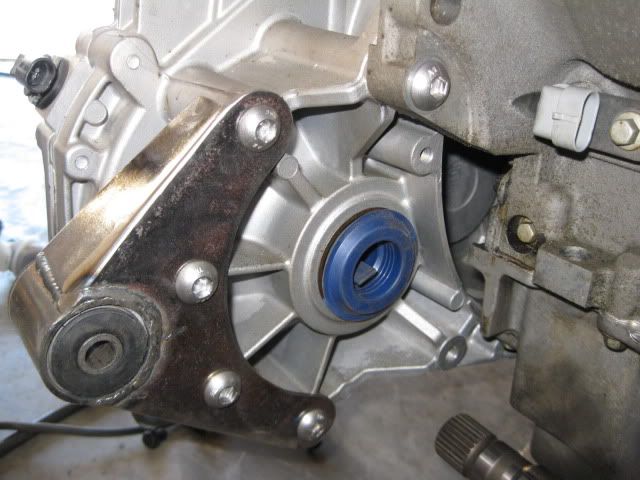

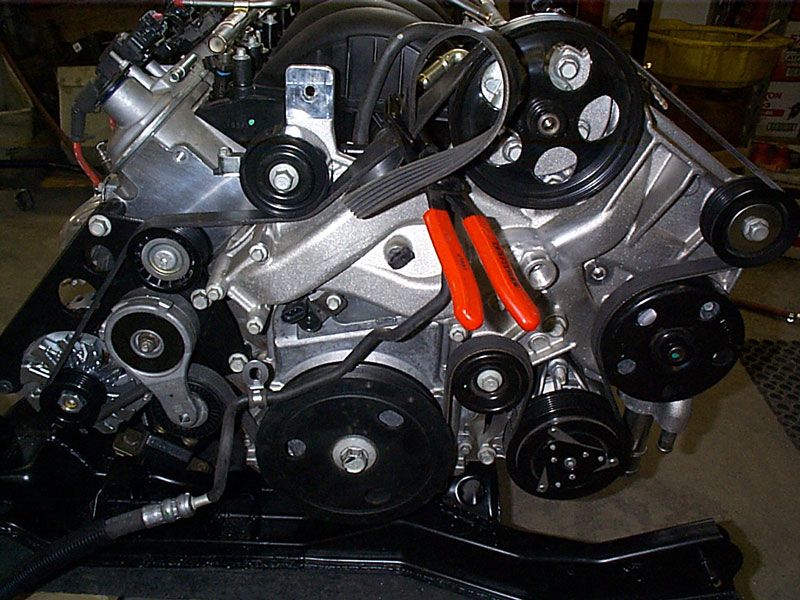

Engineers had to mount this engine sideways so some changes were made. The crankshaft is shorten by 13 mm overall, 3 mm at the flywheel and 10 mm at the accessory drive. This was done to accommodate a more compact accessory drive. Instead of a 2 belt system there is only 1 long serpentine belt, even with this to save space there is only about 2 inches between the crankshaft pulley and the passenger side wheel well. The water pump is mounted off center with elongated passages to connect to the block (see picture). Also a rear facing intake manifold was designed. To ensure proper oiling during high-g cornering the oil pan has special baffles built in. Since Displacement on Demand uses oil for activation an oil pump with 31% more flow than previous LS2 type oil pumps is used.

Displacement: 325ci (5328cc)

Compression Ratio: 10:1 (premium fuel is recommended)

Bore x Stroke: 3.78" x 3.622" (96mm x 92mm)

Firing Order: 1-8-7-2-6-5-4-3

Horsepower: 303 hp @ 5600 rpm

Torque: 323 lb-ft @ 4400 rpm

Fuel Cut-off: 6100 rpm

5.3L LS4 V8

Total Engine Weight (Dry):

[/glow]

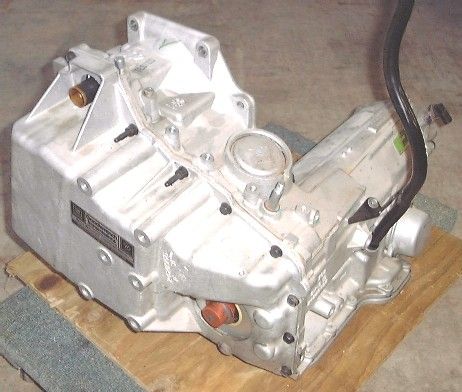

Transmission Specs

RPO / Info: MN7 (has 258mm torque converter and heavy duty gearbox; manumatic/TAPShift option)

5-postion shift quadrant: P R N D M

Total Weight (wet): 214 lbs

Fluid Capacity: 13.4 qt

Gear Ratios: 1st: 2.92

2nd: 1.56

3rd: 1.00

4th: 0.70

Rev: 2.38

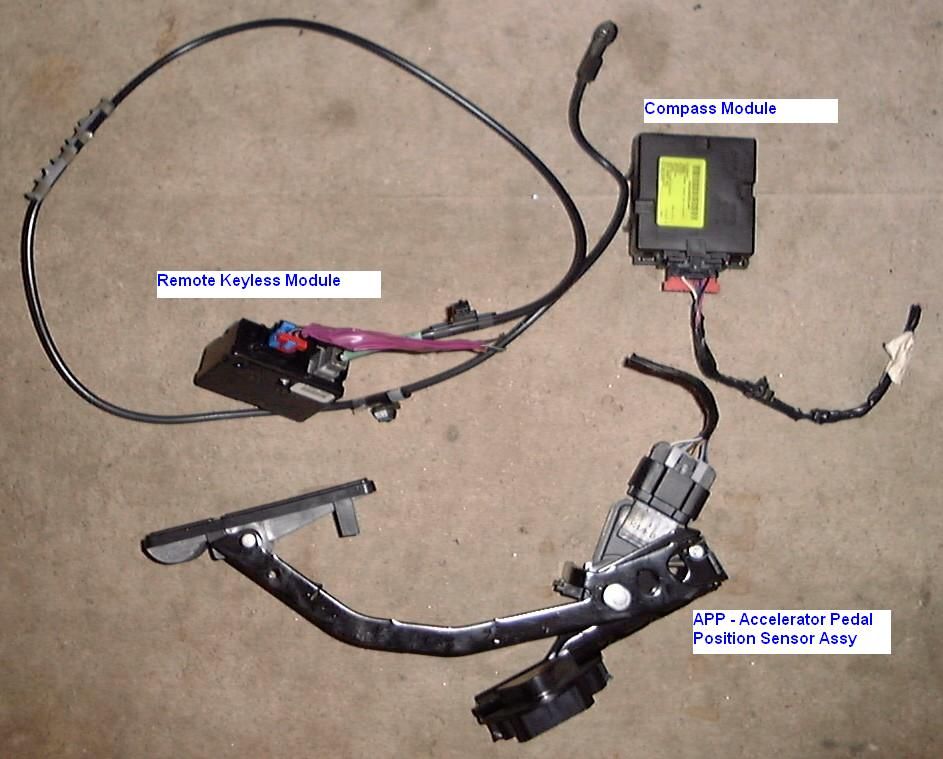

The LS4 is the poor stepchild of the LS series. Used in FWD cars with transmission mounted starter. Small GM V6 bellhousing pattern. Lots available at decent prices. Only 300HP! For the starter the Fiero guys machine the bellhousing and make a bracket. Since it only came with a automatic you would need a custom flywheel. My idea would use a block plate,Northstar starter,2.2 flywheel redrilled and 2.2 belhousing. Would look similar to 215/Rover setup. Most guys do away with the DOD (Displacement on demand) lifters. They have broken and caused oil usage issues. There is some misinformation that the hi-volume oil pump will suck the pan dry. You can improve oil drain back and use the 40lb relief spring. It is a popular upgrade for the LS racers. You can convert the front cover to the better RWD setup or there is a spacer kit to use the Big Block Chevy electric water pump. All the same aftermarket stuff will work with this motor. If you use the LS2 intake,LS3 headers,LS6 cam, lifters and valve springs for an easy 400HP. Here are some pictures of aftermarket oil pan,front pulleys and a good looking motor without the ugly coils on the valve covers.

New Update on Custom Cam

I got my recommendation from Patrick Guerra. I will get a custom grind from Cam Motion; Danny Griffin has already answered some of my questions. The overall specs are as follows. (this is for 425 whp...)

(at .050)

intake 228

exh 232

LSA 113

intake CL 109 degrees

intake valve opens 5 BTDC

intake valve closes 43 ABDC

exh valve opens 53 BBDC

exh valve closes 1 BTDC

exh CL 117 deg

overlap 4 deg

lift is .626 for both.

lobes are .368" custom grind; still using 1.7 stock rockers;

.051 MLS head gasket; 10:1 stock CR; 7.75 DCR (so I think I'm still good for pump gas!!)

recommended; .660 dual springs with Ti retainers; 7.4" Chrome moly pushrods;

its a big cam for a 5.3L but my 425WHP goal requires it.

Other: it should still drop to an idle when taking my foot off the gas. I am deleting the DoD.

Rev limiter is set for 7K.

The oil pan has been touted as having internal baffles... NOPE. It is empty. So I might do something. There is a wind age tray as most engines have now.The stock LS 4 oil pump is higher pressure than some other LS engines.

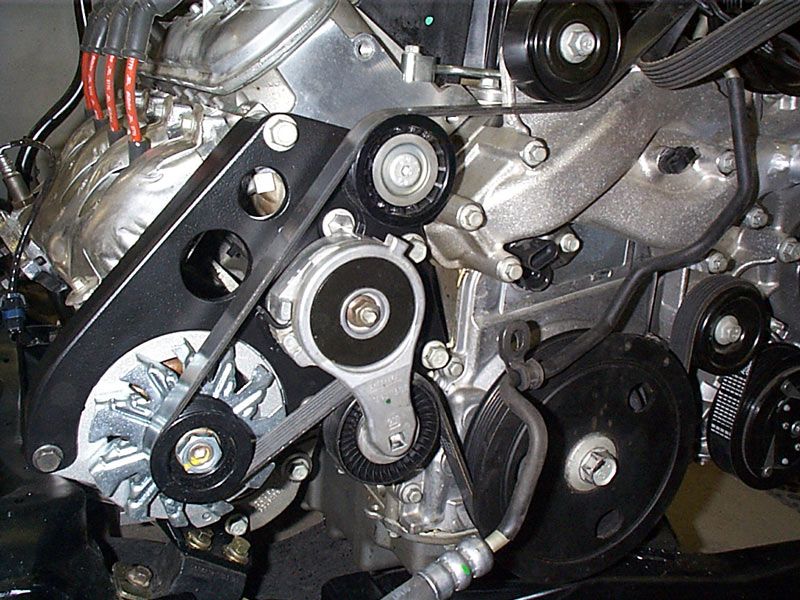

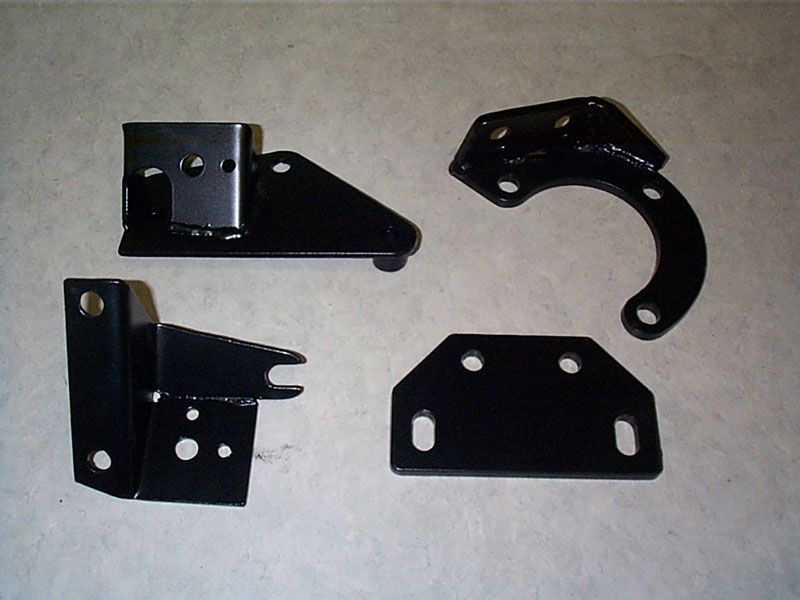

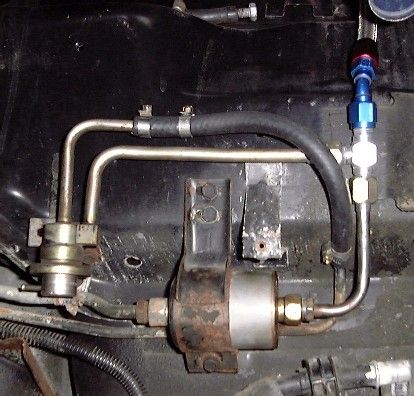

The first major problem discovered during the test fit of the engine was the stock alternator location. The alternator needs to be relocated and the belt re-routed away from the strut tower. The LS4 charging system is computer controlled, using feedback from a current sensor on the positive battery cable. The body control module uses a signal from the current sensor to generate a signal which controls the alternator.

not installing a BCM with this swap, and to simplify wiring, I chose to use a " Fiero alternator ". The only available location for the alternator is on the back of the engine, above the right axle. This is also the location of the stock belt tensioner, so a new tensioning system needed to be designed.

http://www.fullthrottlev6.com/forums/showthread.php?19501-4T65E-FAQ-with-the-FTV6-exclusive-stall-guide

http://www.fullthrottlev6.com/forums/showthread.php?19501-4T65E-FAQ-with-the-FTV6-exclusive-stall-guide